Advanced Recycling

Advanced Recycling

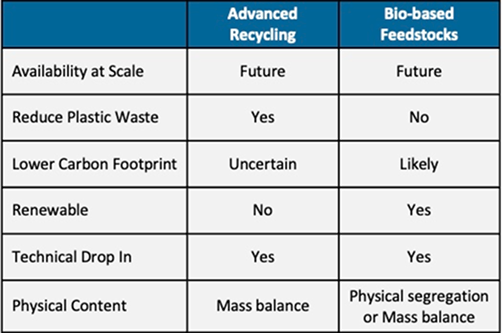

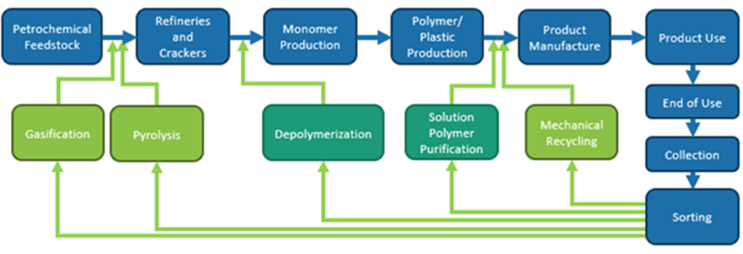

Advanced Composites supports the transition toward a more circular plastics economy through advanced (chemical) recycling technologies. This innovative approach breaks down post-consumer and post-industrial plastic waste into its original molecular building blocks through processes such as pyrolysis, gasification, and depolymerization. These recovered molecules are then reintroduced into the existing production stream—at the refinery, monomer, or polymer stages—to create new materials that are chemically identical to virgin-grade plastics.

The result is a technical drop-in solution that offers high-performance materials while addressing one of the industry’s most urgent environmental challenges: plastic waste. Chemically recycled polypropylene and olefinic elastomers can be seamlessly integrated into our manufacturing processes without requiring reformulation or process changes. While commercial-scale availability is still on the horizon, advanced recycling holds significant potential for reducing waste and enabling mass balance-certified content in automotive-grade compounds. As we help our customers move toward sustainability goals, Advanced Composites remains committed to supporting this next-generation recycling pathway.