Bio Polymers

Bio Polymers

At Advanced Composites, we are committed to building a more sustainable future for the automotive industry—starting with the materials that power it. Our bio-based polymers are derived from renewable resources such as corn and other plant-based feedstocks, offering a carbon-negative alternative to conventional petroleum-based plastics. These materials are designed as true technical drop-ins, meaning they can be processed on existing equipment and deliver the same mechanical and aesthetic performance as virgin grades—without disrupting supply chains or manufacturing operations.

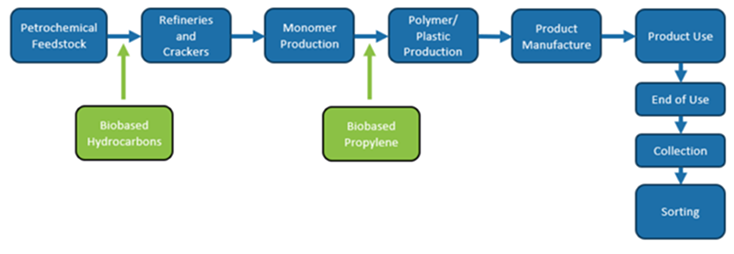

Bio-based content can be introduced at multiple points in the plastic production lifecycle, such as through biobased hydrocarbons or biobased propylene. As shown in the lifecycle graphic, these renewable inputs can be seamlessly integrated into the same infrastructure used for traditional petrochemical feedstocks, making them a practical solution for manufacturers looking to reduce environmental impact. While they do not reduce plastic waste directly, they likely reduce carbon footprint and offer a renewable, physically traceable option through either mass balance or physical segregation.

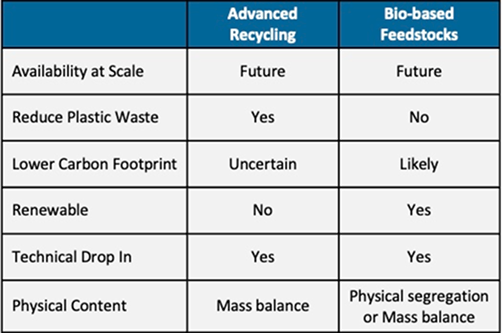

As the industry explores both advanced recycling and bio-based feedstocks, the comparison chart illustrates key distinctions. Advanced recycling supports circularity by reducing plastic waste but has uncertainty around carbon benefits and scalability. In contrast, bio-based feedstocks provide a more renewable pathway and are more likely to result in carbon reductions—though they rely on future scalability and new sourcing methods. Advanced Composites continues to invest in both pathways, giving our partners sustainable choices without sacrificing performance or reliability.

To Learn More about how we use Bio-Polymers, contact us.